Filtration is one of the most essential separation techniques used in everyday life and scientific applications. Whether you’re brewing coffee or conducting a chemical experiment, filtration plays a vital role in separating solids from liquids or gases. This complete guide will walk you through everything you need to know about filtration. What it is, how it works, its types, and where it’s used.

Introduction to Filtration

Filtration is a physical process used to separate insoluble solids from liquids or gases using a filter medium. The solid particles that do not pass through the filter are called the residue, while the liquid or gas that does is called the filtrate.

This process is essential in maintaining purity, improving product quality, and enabling further analysis or processing of materials.

How Does Filtration Work?

Filtration works on the principle of particle size. The filter medium (such as filter paper, sand, or a membrane) contains tiny holes or pores that allow the fluid to pass while trapping larger solid particles.

The process typically involves:

- Pour the mixture of solid and liquid onto the filter.

- The filter medium captures the solid particles.

- The filtered liquid (filtrate) passes through and is collected below.

Types of Filtration Process

Filtration isn’t a product that would fit in all instances. Depending on the material and purpose, there are several types of filtration:

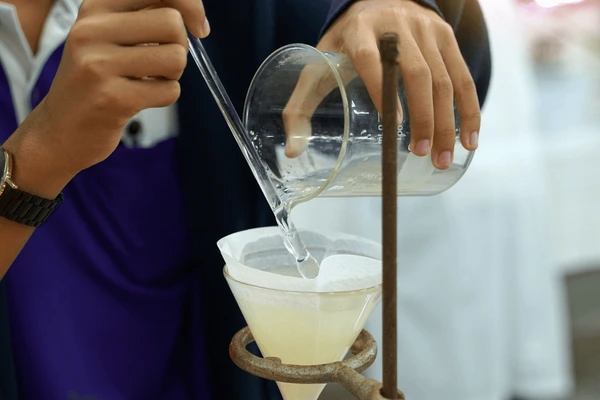

1. Gravity Filtration

This is the most common form used in laboratories and households. It relies on gravity to pull the liquid through a filter paper or porous material.

- Commonly used for: Simple liquid-solid separations

- Equipment: Filter paper, funnel, beaker

2. Vacuum Filtration

In this method, a vacuum is applied below the filter to accelerate the filtration process.

- Ideal for: Rapid filtration of large volumes

- Equipment: Büchner funnel, filter flask, vacuum pump

3. Pressure Filtration

This involves forcing fluid through a filter using pressurized air or gas. It’s used in industrial-scale processes.

- Common in: Chemical manufacturing, food processing

- Advantage: Higher efficiency under pressure

4. Cold Filtration

Designed for substances that may degrade at higher temperatures. It is often used in organic synthesis or when filtering recrystallized compounds.

- Purpose: Preserve temperature-sensitive materials

- Requires: Cooling systems, vacuum filtration setup

5. Hot Filtration

This method prevents the crystallization of solutes during filtration by keeping the solution warm.

- Best for: Purifying compounds in solution

- Uses: Heated apparatus, insulated funnels

6. Mechanical Filtration

In industries and water treatment plants, large-scale mechanical filters.

- It removes particles from liquids or gases.

7. Biological and Chemical Filtration

Used in aquariums and wastewater treatment.

- It removes dissolved organic matter.

- It removes harmful substances with the help of biological agents or chemicals.

Components of Filtration

Every filtration system includes these essential components:

- Filter Medium: The material through which the mixture passes (e.g., filter paper, sand, membrane filters).

- Support System: Funnels, filtration flasks, or industrial chambers.

- Driving Force: Gravity, vacuum, or pressure to facilitate flow.

- Residue Collection: Container to collect solids that don’t pass through.

Filtration Equipment and Materials

Common materials used for the filtration lab include:

- Filter paper

- Buchner funnel

- Filter funnels

- Vacuum flasks

- Sand filters

- Membrane filters

- Distilled water

The choice of equipment depends on the substance being filtered and the purpose of filtration.

Filtration Techniques in the Laboratory

Paper Filtration

This classic technique involves using filter paper in a funnel to separate a solid from a liquid.

- Easy setup and disposal

- Common in chemistry labs and educational settings

Centrifugal Filtration

A hybrid method where centrifugal force helps push particles through the filter medium.

- Often used for: Biological samples, cellular components

Membrane Filtration

Employs microporous membranes to filter out bacteria, viruses, and particulates.

- Essential in: Pharmaceuticals, water treatment, food industries

Applications of Filtration in Everyday Life and Industry

Filtration is not limited to the lab; it’s all over in our daily routines and critical in various industries.

1. Water Purification

One of the most critical uses. Filters remove sediments, pathogens, chlorine, and metals from drinking water.

- Methods include: Activated carbon filters, reverse osmosis, and ceramic filters

2. Air Filtration

Floating particles are removed from indoor and industrial air using HEPA filters, electrostatic precipitators, and fiber mesh systems.

- Protects against: Allergens, dust, pollutants

3. Food and Beverage Industry

Used in the clarification of juices, beer, wine, and the removal of particulates from syrups, oils, and more.

4. Pharmaceutical Manufacturing

Ensures the purity of chemical compounds and separates active pharmaceutical ingredients (APIs) from excipients.

5. Oil and Petroleum Sector

Crucial in refining, where solids are removed from crude oil, lubricants, and fuels.

Advantages of Filtration

The benefits of filtration processes are far-reaching:

- Improved purity and quality of substances

- Prevention of contamination

- Efficient separation without requiring chemical changes

- Cost-effective and often eco-friendly

- Versatile across countless applications

Factors Affecting Filtration Efficiency

The efficacy of a filtration process depends on several parameters:

- The pore size of the filter medium

- Viscosity and temperature of the fluid

- Particle size and concentration

- Flow rate and pressure applied

- Compatibility of the filter material with the mixture

Modern Innovations in Filtration

With technological advancements, modern filtration systems are becoming more specialized and automated. Some notable innovations include:

- Nanofiltration membranes capable of filtering molecules as small as 0.001 microns

- Self-cleaning filters that reduce maintenance downtime

- AI-driven filtration systems for real-time process optimization

- Green filtration technologies focusing on sustainability and lower energy consumption

How to Choose the Right Filtration Method

When deciding on the right filtration approach, consider:

- Nature of the mixture – liquid-solid, gas-solid, etc.

- Sensitivity of components – temperature, pH, pressure

- Required purity level

- Throughput volume

- Budget and infrastructure availability

Conclusion:

Filtration is an essential technique in both fundamental science and applied industries. Its ability to purify, separate, and refine materials makes it indispensable in maintaining health, safety, and efficiency. As industries evolve and environmental concerns grow, the importance of effective filtration systems will only continue to rise.

Whether you’re a student, researcher, engineer, or manufacturer, understanding the variation of filtration can significantly improve the quality and outcome of your work.

What is the definition of filtration?

It is a physical process used to separate insoluble solids from liquids or gases using a filter medium. The solid particles that do not pass through the filter are called the residue, while the liquid or gas that does is called the filtrate.

This process is essential in maintaining purity, improving product quality, and enabling further analysis or processing of materials.

How Does it Work?

It works on the principle of particle size. The filter medium (such as filter paper, sand, or a membrane) contains tiny holes or pores that allow the fluid to pass while trapping larger solid particles.

The process typically involves:

Pouring the mixture of solid and liquid onto the filter.

The filter medium captures the solid particles.

The filtered liquid (filtrate) passes through and is collected below.

Types of Process

Filtration isn’t a product that would fit in all instances. Depending on the material and purpose, there are several types of filtration:

1. Gravity

This is the most common form used in laboratories and households. It relies on gravity to pull the liquid through a filter paper or porous material.

Commonly used for: Simple liquid-solid separations

Equipment: Filter paper, funnel, beaker

2. Vacuum

In this method, a vacuum is applied below the filter to accelerate the filtration process.

Ideal for: Rapid filtration of large volumes

Equipment: Büchner funnel, filter flask, vacuum pump

3. Pressure

This involves forcing fluid through a filter using pressurized air or gas. It’s used in industrial-scale processes.

Common in: Chemical manufacturing, food processing

Advantage: Higher efficiency under pressure

4. Cold

Designed for substances that may degrade at higher temperatures. It is often used in organic synthesis or when filtering recrystallized compounds.

Purpose: Preserve temperature-sensitive materials

Requires: Cooling systems, vacuum filtration setup

5. Hot

This method prevents the crystallization of solutes during filtration by keeping the solution warm.

Best for: Purifying compounds in solution

Uses: Heated apparatus, insulated funnels

6. Mechanical

In industries and water treatment plants, large-scale mechanical filters.

It removes particles from liquids or gases.

7. Biological and Chemical

Used in aquariums and wastewater treatment.

It removes dissolved organic matter.

It removes harmful substances with the help of biological agents or chemicals.

Components

Every system includes these essential components:

Filter Medium: The material through which the mixture passes (e.g., filter paper, sand, membrane filters).

Support System: Funnels, flasks, or industrial chambers.

Driving Force: Gravity, vacuum, or pressure to facilitate flow.

Residue Collection: Container to collect solids that don’t pass through.

Equipment and Materials

Common materials used for filtration lab include:

Filter paper

Buchner funnel

Filter funnels

Vacuum flasks

Sand filters

Membrane filters

Distilled water

The choice of equipment depends on the substance being filtered and the purpose of filtration.

Techniques in the Laboratory

Paper Filtration

This classic technique involves using filter paper in a funnel to separate a solid from a liquid.

Easy setup and disposal

Common in chemistry labs and educational settings

Centrifugal Filtration

A hybrid method where centrifugal force helps push particles through the filter medium.

Often used for: Biological samples, cellular components

Membrane

Employs microporous membranes to filter out bacteria, viruses, and particulates.

Essential in: Pharmaceuticals, water treatment, food industries

Applications in Everyday Life and Industry

Filtration is not limited to the lab; it’s all over in our daily routines and critical in various industries.

1. Water Purification

One of the most critical uses. Filters remove sediments, pathogens, chlorine, and metals from drinking water.

Methods include: Activated carbon filters, reverse osmosis, ceramic filters

2. Air Filtration

Floating particles are removed from indoor and industrial air using HEPA filters, electrostatic precipitators, and fiber mesh systems.

Protects against: Allergens, dust, pollutants

3. Food and Beverage Industry

Used in the clarification of juices, beer, wine, and the removal of particulates from syrups, oils, and more.

4. Pharmaceutical Manufacturing

Ensures the purity of chemical compounds and separates active pharmaceutical ingredients (APIs) from excipients.

5. Oil and Petroleum Sector

Crucial in refining, where solids are removed from crude oil, lubricants, and fuels.

Advantages of Filtration

The benefits of filtration processes are far-reaching:

Improved purity and quality of substances

Prevention of contamination

Efficient separation without requiring chemical changes

Cost-effective and often eco-friendly

Versatile across countless applications

Factors Affecting Filtration Efficiency

The efficacy of a filtration process depends on several parameters:

The pore size of the filter medium

Viscosity and temperature of the fluid

Particle size and concentration

Flow rate and pressure applied

Compatibility of the filter material with the mixture

Modern Innovations in Filtration

With technological advancements, modern filtration systems are becoming more specialized and automated. Some notable innovations include:

Nanofiltration membranes capable of filtering molecules as small as 0.001 microns

Self-cleaning filters that reduce maintenance downtime

AI-driven filtration systems for real-time process optimization

Green filtration technologies focusing on sustainability and lower energy consumption

How to Choose the Right Filtration Method

When deciding on the right filtration approach, consider:

Nature of the mixture – liquid-solid, gas-solid, etc.

Sensitivity of components – temperature, pH, pressure

Required purity level

Throughput volume

Budget and infrastructure availability

Conclusion:

Filtration is an essential technique in both fundamental science and applied industries. Its ability to purify, separate, and refine materials makes it indispensable in maintaining health, safety, and efficiency. As industries evolve and environmental concerns grow, the importance of effective filtration systems will only continue to rise.

Whether you’re a student, researcher, engineer, or manufacturer, understanding the variation of filtration can significantly improve the quality and outcome of your work.

What are the types of filtration?

1. Gravity

This is the most common form used in laboratories and households. It relies on gravity to pull the liquid through a filter paper or porous material.

Commonly used for: Simple liquid-solid separations

Equipment: Filter paper, funnel, beaker

2. Vacuum

In this method, a vacuum is applied below the filter to accelerate the process.

Ideal for: large volumes

Equipment: Büchner funnel, filter flask, vacuum pump

3. Pressure

This involves forcing fluid through a filter using pressurized air or gas. It’s used in industrial-scale processes.

Common in: Chemical manufacturing, food processing

Advantage: Higher efficiency under pressure

4. Cold

Designed for substances that may degrade at higher temperatures. It is often used in organic synthesis or when filtering recrystallized compounds.

Purpose: Preserve temperature-sensitive materials

Requires: Cooling systems, vacuum filtration setup

5. Hot

This method prevents the crystallization of solutes during filtration by keeping the solution warm.

Best for: Purifying compounds in solution

Uses: Heated apparatus, insulated funnels

6. Mechanical

In industries and water treatment plants, large-scale mechanical filters.

It removes particles from liquids or gases.

7. Biological and Chemical

Used in aquariums and wastewater treatment.

It removes dissolved organic matter.

It removes harmful substances with the help of biological agents or chemicals.

What is the filtration class 9th?

What is Filtration?

It is a physical process used to separate insoluble solids from liquids or gases using a filter medium. The solid particles that do not pass through the filter are called the residue, while the liquid or gas that does is called the filtrate.

This process is essential in maintaining purity, improving product quality, and enabling further analysis or processing of materials.

How Does it Work?

It works on the principle of particle size. The filter medium (such as filter paper, sand, or a membrane) contains tiny holes or pores that allow the fluid to pass while trapping larger solid particles.

The process typically involves:

Pouring the mixture of solid and liquid onto the filter.

The filter medium captures the solid particles.

The filtered liquid (filtrate) passes through and is collected below.

Types of this Process

Filtration isn’t a product that would fit in all instances. Depending on the material and purpose, there are several types of filtration:

1. Gravity

This is the most common form used in laboratories and households. It relies on gravity to pull the liquid through a filter paper or porous material.

Commonly used for: Simple liquid-solid separations

Equipment: Filter paper, funnel, beaker

2. Vacuum

In this method, a vacuum is applied below the filter to accelerate the process.

Ideal for: Rapid filtration of large volumes

Equipment: Büchner funnel, filter flask, vacuum pump

3. Pressure

This involves forcing fluid through a filter using pressurized air or gas. It’s used in industrial-scale processes.

Common in: Chemical manufacturing, food processing

Advantage: Higher efficiency under pressure

4. Cold

Designed for substances that may degrade at higher temperatures. It is often used in organic synthesis or when filtering recrystallized compounds.

Purpose: Preserve temperature-sensitive materials

Requires: Cooling systems, vacuum filtration setup

5. Hot

This method prevents the crystallization of solutes during filtration by keeping the solution warm.

Best for: Purifying compounds in solution

Uses: Heated apparatus, insulated funnels

6. Mechanical

In industries and water treatment plants, large-scale mechanical filters.

It removes particles from liquids or gases.

7. Biological and Chemical

Used in aquariums and wastewater treatment.

It removes dissolved organic matter.

It removes harmful substances with the help of biological agents or chemicals.

Components

Every system includes these essential components:

Filter Medium: The material through which the mixture passes (e.g., filter paper, sand, membrane filters).

Support System: Funnels, flasks, or industrial chambers.

Driving Force: Gravity, vacuum, or pressure to facilitate flow.

Residue Collection: Container to collect solids that don’t pass through.

Equipment and Materials

Common materials used for filtration lab include:

Filter paper

Buchner funnel

Filter funnels

Vacuum flasks

Sand filters

Membrane filters

Distilled water

The choice of equipment depends on the substance being filtered and the purpose of this process.

Techniques in the Laboratory

Paper Filtration

This classic technique involves using filter paper in a funnel to separate a solid from a liquid.

Easy setup and disposal

Common in chemistry labs and educational settings

Centrifugal Filtration

A hybrid method where centrifugal force helps push particles through the filter medium.

Often used for: Biological samples, cellular components

Membrane Filtration

Employs microporous membranes to filter out bacteria, viruses, and particulates.

Essential in: Pharmaceuticals, water treatment, food industries

Applications in Everyday Life and Industry

It is not limited to the lab; it’s ubiquitous in our daily routines and critical in various industries.

1. Water Purification

One of the most critical uses. Filters remove sediments, pathogens, chlorine, and metals from drinking water.

Methods include: Activated carbon filters, reverse osmosis, ceramic filters

2. Air

Floating particles are removed from indoor and industrial air using HEPA filters, electrostatic precipitators, and fiber mesh systems.

Protects against: Allergens, dust, pollutants

3. Food and Beverage Industry

Used in the clarification of juices, beer, wine, and the removal of particulates from syrups, oils, and more.

4. Pharmaceutical Manufacturing

Ensures the purity of chemical compounds and separates active pharmaceutical ingredients (APIs) from excipients.

5. Oil and Petroleum Sector

Crucial in refining, where solids are removed from crude oil, lubricants, and fuels.

Advantages

The benefits of processes are far-reaching:

Improved purity and quality of substances

Prevention of contamination

Efficient separation without requiring chemical changes

Cost-effective and often eco-friendly

Versatile across countless applications

Factors Affecting Efficiency

The efficacy of a process depends on several parameters:

The pore size of the filter medium

Viscosity and temperature of the fluid

Particle size and concentration

Flow rate and pressure applied

Compatibility of the filter material with the mixture

Modern Innovations

With technological advancements, modern systems are becoming more specialized and automated. Some notable innovations include:

Nanofiltration membranes capable of filtering molecules as small as 0.001 microns

Self-cleaning filters that reduce maintenance downtime

AI-driven systems for real-time process optimization

Green technologies focusing on sustainability and lower energy consumption

How to Choose the Right Method

When deciding on the right approach, consider:

Nature of the mixture – liquid-solid, gas-solid, etc.

Sensitivity of components – temperature, pH, pressure

Required purity level

Throughput volume

Budget and infrastructure availability

Conclusion:

It is an essential technique in both fundamental science and applied industries. Its ability to purify, separate, and refine materials makes it indispensable in maintaining health, safety, and efficiency. As industries evolve and environmental concerns grow, the importance of effective systems will only continue to rise.

Whether you’re a student, researcher, engineer, or manufacturer, understanding the variation of this can significantly improve the quality and outcome of your work.

What are the applications of filtration?

It is not limited to the lab; it’s all over in our daily routines and critical in various industries.

1. Water Purification

One of the most critical uses. Filters remove sediments, pathogens, chlorine, and metals from drinking water.

Methods include: Activated carbon filters, reverse osmosis, ceramic filters

2. Air

Floating particles are removed from indoor and industrial air using HEPA filters, electrostatic precipitators, and fiber mesh systems.

Protects against: Allergens, dust, pollutants

3. Food and Beverage Industry

Used in the clarification of juices, beer, wine, and the removal of particulates from syrups, oils, and more.

4. Pharmaceutical Manufacturing

Ensures the purity of chemical compounds and separates active pharmaceutical ingredients (APIs) from excipients.

5. Oil and Petroleum Sector

Crucial in refining, where solids are removed from crude oil, lubricants,

What is the process of filtration?

It is a physical process used to separate insoluble solids from liquids or gases using a filter medium. The solid particles that do not pass through the filter are called the residue, while the liquid or gas that does is called the filtrate.

This process is essential in maintaining purity, improving product quality, and enabling further analysis or processing of materials.

How Does the Filtration Process Work?

It works on the principle of particle size. The filter medium (such as filter paper, sand, or a membrane) contains tiny holes or pores that allow the fluid to pass while trapping larger solid particles.

The process typically involves:

Pouring the mixture of solid and liquid onto the filter.

The filter medium captures the solid particles.

The filtered liquid (filtrate) passes through and is collected below.

Types of this Process

It isn’t a product that would fit in all instances. Depending on the material and purpose, there are several types of filtration:

1. Gravity

This is the most common form used in laboratories and households. It relies on gravity to pull the liquid through a filter paper or porous material.

Commonly used for: Simple liquid-solid separations

Equipment: Filter paper, funnel, beaker

2. Vacuum

In this method, a vacuum is applied below the filter to accelerate this process.

Ideal for:

Equipment: Büchner funnel, filter flask, vacuum pump

3. Pressure

This involves forcing fluid through a filter using pressurized air or gas. It’s used in industrial-scale processes.

Common in: Chemical manufacturing, food processing

Advantage: Higher efficiency under pressure

4. Cold

Designed for substances that may degrade at higher temperatures. It is often used in organic synthesis or when filtering recrystallized compounds.

Purpose: Preserve temperature-sensitive materials

Requires: Cooling systems, vacuum filtration setup

5. Hot

This method prevents the crystallization of solutes by keeping the solution warm.

Best for: Purifying compounds in solution

Uses: Heated apparatus, insulated funnels

6. Mechanical

In industries and water treatment plants, large-scale mechanical filters.

It removes particles from liquids or gases.

7. Biological and Chemical

Used in aquariums and wastewater treatment.

It removes dissolved organic matter.

It removes harmful substances with the help of biological agents or chemicals.

Components of

Every system includes these essential components:

Filter Medium: The material through which the mixture passes (e.g., filter paper, sand, membrane filters).

Support System: Funnels, flasks, or industrial chambers.

Driving Force: Gravity, vacuum, or pressure to facilitate flow.

Residue Collection: Container to collect solids that don’t pass through.

Equipment and Materials

Common materials used for filtration lab include:

Filter paper

Buchner funnel

Filter funnels

Vacuum flasks

Sand filters

Membrane filters

Distilled water

The choice of equipment depends on the substance being filtered and the purpose of the process.

Different Techniques in the Laboratory

Paper

This classic technique involves using filter paper in a funnel to separate a solid from a liquid.

Easy setup and disposal

Common in chemistry labs and educational settings

Centrifugal

A hybrid method where centrifugal force helps push particles through the filter medium.

Often used for: Biological samples, cellular components

Membrane

Employs microporous membranes to filter out bacteria, viruses, and particulates.

Essential in: Pharmaceuticals, water treatment, food industries

Applications in Everyday Life and Industry

It is not limited to the lab; it’s all over in our daily routines and critical in various industries.

1. Water Purification

One of the most critical uses. Filters remove sediments, pathogens, chlorine, and metals from drinking water.

Methods include: Activated carbon filters, reverse osmosis, ceramic filters

2. Air

Floating particles are removed from indoor and industrial air using HEPA filters, electrostatic precipitators, and fiber mesh systems.

Protects against: Allergens, dust, pollutants

3. Food and Beverage Industry

Used in the clarification of juices, beer, wine, and the removal of particulates from syrups, oils, and more.

4. Pharmaceutical Manufacturing

Ensures the purity of chemical compounds and separates active pharmaceutical ingredients (APIs) from excipients.

5. Oil and Petroleum Sector

Crucial in refining, where solids are removed from crude oil, lubricants, and fuels.

Advantages

The benefits of filtration processes are far-reaching:

Improved purity and quality of substances

Prevention of contamination

Efficient separation without requiring chemical changes

Cost-effective and often eco-friendly

Versatile across countless applications

Factors Affecting

The efficacy of a process depends on several parameters:

The pore size of the filter medium

Viscosity and temperature of the fluid

Particle size and concentration

Flow rate and pressure applied

Compatibility of the filter material with the mixture

Modern Innovations

With technological advancements, modern systems are becoming more specialized and automated. Some notable innovations include:

Nanofiltration membranes capable of filtering molecules as small as 0.001 microns

Self-cleaning filters that reduce maintenance downtime

AI-driven systems for real-time process optimization

Green technologies focusing on sustainability and lower energy consumption

How to Choose the Right Method

When deciding on the right this approach, consider:

Nature of the mixture – liquid-solid, gas-solid, etc.

Sensitivity of components – temperature, pH, pressure

Required purity level

Throughput volume

Budget and infrastructure availability

Conclusion:

It is an essential technique in both fundamental science and applied industries. Its ability to purify, separate, and refine materials makes it indispensable in maintaining health, safety, and efficiency. As industries evolve and environmental concerns grow, the importance of effective filtration systems will only continue to rise.

Whether you’re a student, researcher, engineer, or manufacturer, understanding the variation of this can significantly improve the quality and outcome of your work.

2 thoughts on “Filtration”